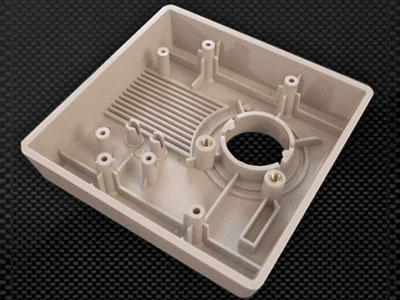

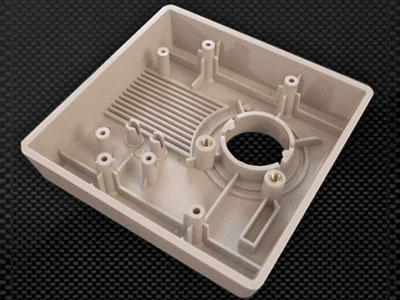

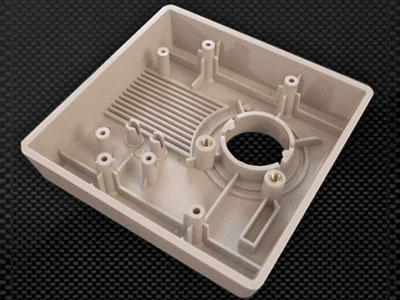

ABS Injection Molding

Trident Components has extensive experience in Acrylonitrile-butadiene-styrene, or ABS injection molding. Our ABS injection molding service creates components used in various industries and for a wide variety of applications. Our state-of-the-art equipment will quickly take your job from start to finish with quality results.

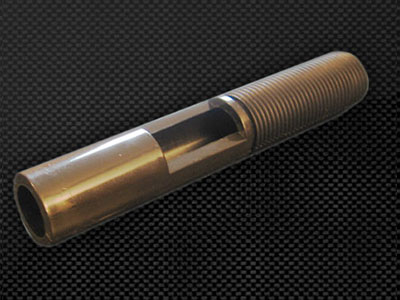

PVC – Polyvinyl Chloride Injection Molding

Trident Components offers polyvinyl chloride, or PVC, injection molding. We have state-of-the-art facilities, and our production capabilities and warehousing services can accurately and cost-effectively meet all of your injection molding needs. Let us know how we can help you with your PVC injection molding projects today.

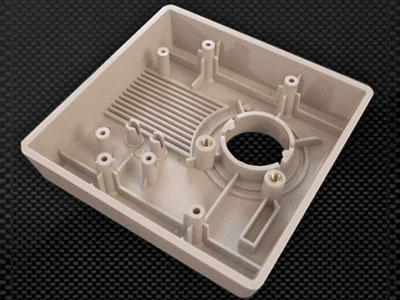

Nylon (Glass Filled) Injection Molding

Trident Components offers the highest quality nylon injection molding, or glass filled injection molding. We have top-notch facilities, and our production capabilities and warehousing services can accurately and cost-effectively meet the demands of any size project to meet your most demanding plastic molding needs. If you have a custom project, let our service team offer a low cost solution.

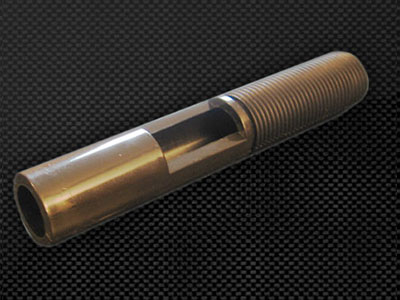

Acrylic Polymer Injection Molding

Trident Components offers acrylic and acrylic polymer injection molding for all of your injection molding needs. From its use in medical equipment to electronic devices, acrylic and its polymers are fundamental components to any industry. Trident offers state-of-the-art facilities, combined production capabilities and warehousing services, enabling us to accurately and cost-effectively meet the demands of any size project.

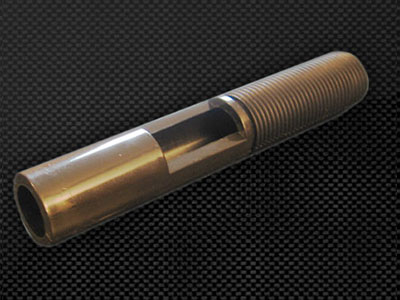

Polyethylene Injection Molding

Trident Components has extensive experience in polyethylene injection molding. Polyethylene’s versatility make it an ideal replacement for metal and rubber parts, offering exceptional and cost-effective performance capabilities suitable for many industries. We have state-of-the-art facilities, production capabilities, and warehousing services to accurately and cost-effectively meet the demands of any size project.

Polypropylene (PP) Injection Molding

Trident Components has extensive experience in polypropylene, or PP, injection molding. Versatile and strong, PP can be molded into forms used in just about every industry. Medical, sporting goods, auto and other consumer industries use these products every day. We have state-of-the-art facilities and our production capabilities can meet the demands of any custom project. Let us specifically design something for you today.

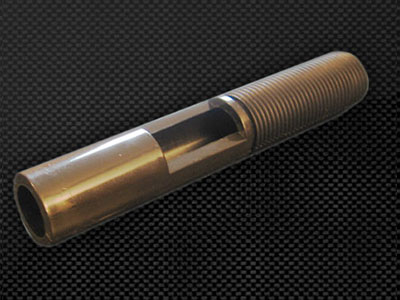

Polyurethane Injection Molding

Trident Components has extensive experience in polyurethane injection molding. We have state-of-the-art facilities, production capabilities, and warehousing services to accurately and cost-effectively meet the demands of any size project. Polyurethane’s versatility make it an ideal replacement for metal and rubber parts, offering exceptional and cost-effective performance capabilities suitable for many industries.

PTFE Injection Molding

Trident Components has extensive experience in polytetrafluoroethylene, or PTFE injection molding. With state-of-the-art facilities, our production capabilities, warehousing services and blanket ordering system, we accurately and cost-effectively meet the demands of any size project. PTFE is commonly known by the DuPont brand name Teflon, and has numerous applications.

Polymethyl Methacrylate (PMMA) Injection Molding

Trident Components’ long history of working with polymethyl methacrylate, or PMMA, injection molding makes us an industry leader. With our state-of-the-art facilities, production capabilities, and warehousing services, can accurately and cost-effectively meet the demands of any sized project. Commonly known as acrylic and by the Plexiglas® trademark, PMMA is a glass substitute that offers many exceptional properties.

Low Density Polyethylene (LDPE) Injection Molding

Trident Components has experience in low density polyethylene, or LDPE, injection molding. Lightweight and flexible, LDPE can be injection-molded for a variety of applications. We can warehouse your orders inside our modern facilities, and accurately ship your products on time with our convenient and cost-effective blanket ordering system. Our services and quality parts will meet the demands of any sized project.

HDPE Injection Molding

Trident Components has extensive experience in high density polyethylene, or HDPE injection molding. Commonly favored for its strength, low cost, and impact resistance, HDPE can be molded into a variety of shapes and products. At Trident, we pride ourselves on our custom production capabilities, cutting-edge facilities, and warehousing services to accurately and cost-effectively meet the demands of any sized project.

Polyethylene Terephthalate (PET) Injection Molding

Trident Components has extensive knowledge of polyethylene terephthalate, or PET, injection molding. Our investment in the latest equipment allows our production capabilities to meet any of your custom production needs. In addition, we offer blanket ordering and warehousing services to accurately and cost-effectively meet the demands of any sized project.